What Is the Best Screed for Underfloor Heating? A Guide

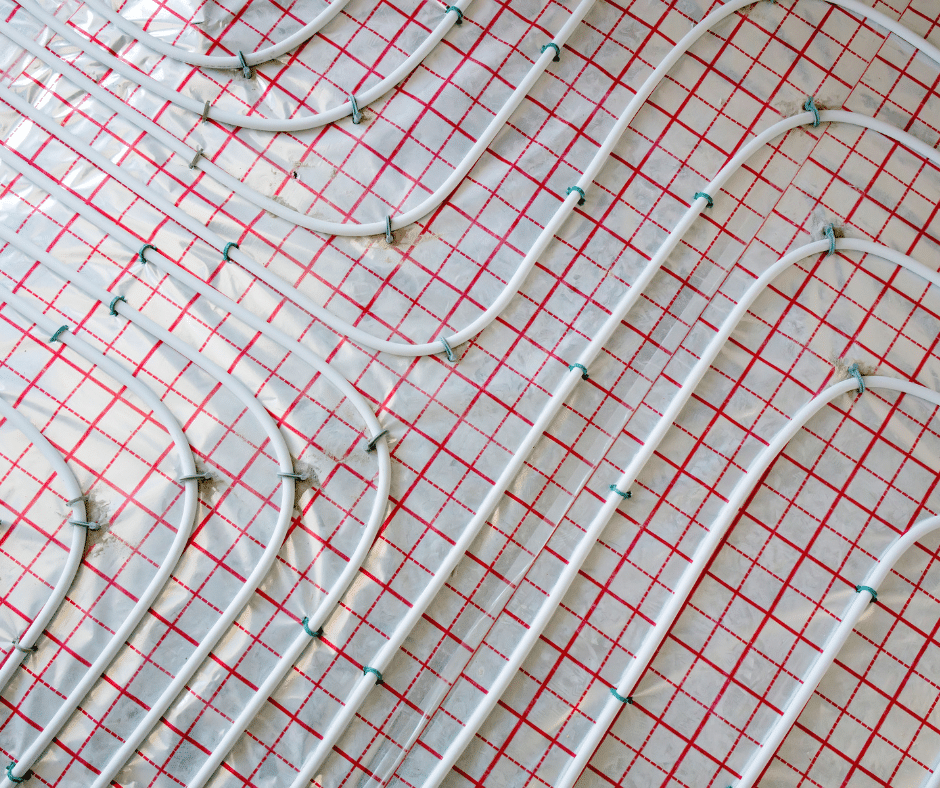

Choosing the right floor screed for your underfloor heating is essential if you want to get the most out of your new heating system. Poor floor screeding can lead to the uneven distribution of heat due to air gaps, reducing the efficiency of your system and making it less cost-effective.

When it comes to the best floor screeds for underfloor heating, liquid screeds are by far the stand out choice due to their unmatched efficiency and versatility. Unlike traditional concrete screeds, liquid screeds boast superior thermal conductivity, allowing heat to transfer quickly and evenly across your flooring. They can also be installed quicker and in thinner layers. This reduces drying time and saves on labour, making them a cost-effective option for property and business owners.

What are Liquid Screeds?

Liquid screeds, also known as flowing screeds, are typically made from anhydrite or calcium sulphate. They offer, as their name suggests, a more “flowing” consistency when applied to surfaces.

More responsive to gravity, liquid screed flows evenly across a surface, filling all of the gaps that might be present. This is perfect for underfloor heating systems as it ensures there are no air gaps left.

Air pockets act as insulators, causing heat to be trapped around the pipes rather than being evenly distributed across the floor.

This leads to hot spots near the pipes and cooler areas elsewhere, reducing the performance of your heating system. This makes it more costly to heat up rooms.

Liquid screeds therefore provide superior thermal efficiency when compared to their concrete counterparts.

What are Concrete Screeds?

Concrete screeds, on the other hand, are made from a sand and cement mixture and are heavier and require more labour to install.

While concrete versions are durable and versatile, they generally take longer to cure and can be more prone to cracking due to shrinkage.

Advantages of Liquid Screeding for Underfloor Heating

- Superior Thermal Efficiency: Liquid screeds fully encapsulate heating pipes, ensuring maximum heat transfer and even heat distribution.

- Faster Installation: Pumpable and easy to apply, they allow for quicker installations, saving on labour costs.

- Reduced Drying Time: These screeds are walkable within 24–48 hours and fully load-bearing in 7 days.

- Minimised Cracking and Shrinkage: They also shrink less and are less prone to cracking, ensuring a durable and stable base.

- Enhanced Strength: With higher compressive and flexural strength than traditional variants, liquid screed is ideal for residential and commercial projects.

Disadvantages

- Higher Initial Cost: Liquid screeds can be more expensive upfront compared to traditional sand and cement options.

- Specialised Equipment Required: Installation requires pumping machinery, which may add to both cost and complexity.

- Curing Sensitivity: They can also be more sensitive to extreme temperatures or humidity, which might affect the curing process and final strength if not properly managed.

Liquid vs Concrete Screeds

| Feature | Liquid Screeds | Concrete Screeds |

| Thermal Efficiency | High thermal conductivity for better heat transfer and quicker heating response. | Lower thermal conductivity, resulting in slower and less efficient heat transfer. |

| Thickness | Can be applied in thinner layers, reducing material use and thermal lag. | Requires a thicker application, increasing weight and slowing heating response. |

| Installation Speed | Quick and easy to install using pumpable methods, saving time and labor | Slower installation process requiring manual leveling and increased labour costs. |

| Drying Time | Walkable within 24–48 hours, can handle loads after 7 days. | Takes longer to cure (up to 28 days), delaying project completion. |

| Cracking and Shrinkage | Low risk of cracking and shrinkage. | Prone to cracking and shrinkage. |

| Strength and Durability | Higher compressive and flexural strength, making it long-lasting and resilient. | Less durable and more prone to damage under heavy loads or stress. |

| Labor and Cost Efficiency | Lower labor requirements due to faster, pumpable application and reduced material needs. | Higher labor costs due to manual processes and thicker layers. |

Can Screed Be Too Thick for Underfloor Heating?

It’s possible for screed to be too thick for underfloor heating performance. While traditional sand and cement screeds often require a thicker layer to cover the heating pipes, this extra thickness can create more thermal mass, meaning your floors will take longer to heat up.

The ideal thickness for underfloor heating should be between 20mm and 50mm. This range ensures efficient heat transfer while maintaining a good level of stability and strength.

If the layer is too thick—say, above 50mm—it can create unnecessary thermal lag. That means your system would take longer to reach the desired temperature, impacting the overall energy efficiency of your system.

Thicker layers also add more weight. However, liquid screeds, with their thinner, more efficient layer, help to strike the perfect balance.

Can Underfloor Heating Cause Screed to Crack?

Underfloor heating, when properly installed, should not cause screed to crack. However, improper installation can lead to issues.

The heat from the system can cause the screed to expand and contract, which is a natural occurrence. If there are no expansion joints or the screed is applied too thickly, this movement could cause cracking.

Liquid screeds, with their minimal shrinkage properties, are much less prone to cracking compared to traditional concrete counterparts. They naturally distribute stress more evenly, especially when laid correctly over underfloor heating pipes.

To minimise cracking risk, it’s important that the screed is installed by professionals who know how to accommodate this natural movement, including proper curing times and any necessary jointing.

What Is the Minimum Depth of Screed for Underfloor Heating?

The minimum depth for screed when installing underfloor heating depends on several factors, such as the type of heating system and the materials used.

However, a general rule of thumb is that the screed should be at least 20mm above the top of the heating pipes.

This is often considered the minimum for ensuring effective heat transfer and sufficient coverage for the pipes.

Ifit is spread is too thin, it may not adequately cover the heating system, leading to heat loss and inefficient heating. On the other hand, if it is too thick (over 50mm), it can increase thermal lag and extend the time it takes for the system to heat up.

Ultimately, the correct depth ensures a balanced heat distribution across the floor, helping you maximise the efficiency of your underfloor heating and create a comfortable living or working space.

FAQs

1. Can liquid screeds be used with all flooring types?

Yes, liquid screeds are compatible with most flooring types, including tiles, stone, and engineered wood. However, certain types of wood flooring may require additional considerations.

2. How soon can I walk on a liquid screed floor?

Most liquid screeds are walkable within 24–48 hours after installation, depending on the specific product and site conditions.

3. Is liquid screed more expensive than concrete screed?

While the initial cost is higher, its faster installation, reduced labour costs, and energy efficiency make it more cost-effective in the long run.

4. Does liquid screed require special preparation?

Yes, the sub-floor should be clean, level, and primed before installation to ensure optimal results.

5. Can liquid screed be used in retrofits?

Yes, liquid screeds are ideal for retrofits, especially with underfloor heating systems, as they require a thinner application and cure quickly.

Contact Us Today

At GM Floor Screeds, we pride ourselves on delivering high-quality screeding solutions that meet and exceed your expectations.

We are liquid screed installation specialists based in the West Midlands, and have years’ of expertise with underfloor heating systems – so you can trust us to handle your project with professionalism and integrity.

If you’re in need of expert screed installation for your underfloor heating, Contact us today for a free, no obligation quote, and discover the benefits of superior screeding for yourself!